Automated warehouse is an automatic storage system by the combination of a solid floors structure rack system with a robot system and the whole system will be controlled by a computerized warehouse management system. Automated warehouse comprises one or more aisles with ranks on both sides where the robot system moves to import and export goods. Automated warehouses are ideal for companies that need to export and import goods at a high speed, which can be many times faster than a normal warehouse. The system allows for optimal use of space due to high density storage in both length and height. This is a product as well as a system that speeds up stock preparation. Automated warehouses bring high efficiency in the process of managing export and import goods. All of these contribute to cost savings and increased productivity. Workflow is carried out safely and easily protecting both the robot system and the staff.

This system is suitable for companies from any field, it is a smart solution that optimizes the process of managing goods, personnel, and space... , to improve the productivity of the warehouse and save maximum costs, not only that, but also contributes to increasing the modern aesthetics of the factory. Therefore, the automatic warehouse has now become popular in the world.

Depending on the quantity and level of import and export of each customer, we will create automatic warehouses in accordance with different structure and operation characteristics to best serve the requirements of goods transportation.

Automated Racking AS/RS - is a solution for automatically sorting, storing and exporting goods with high density, high speed and flexibility to save time with storage space in height up to 20m and unlimited length

Digitizing the warehouse, all information on paper and manual is converted into digital form on the computer, which is very important for the efficiency of information processing and storage.

Convenient for inventory, reduce inventory reasonably, reduce errors in the process of importing and exporting goods.

Easily manage import and export goods and manage inventory.

Reduces labor costs, improves worker productivity, reduces workforce, and increases safety.

Save warehouse space and improve space utilization. Save space many times compared with normal warehouse.

Improve labor productivity and reduce the number of workers.

Suitable for all warehouses, especially for warehouses with many different types of goods.

High bearing capacity, large capacity, increase longevity.

Improve operational quality and ensure safe movement of goods during storage.

There is a conveyor system to improve import and export efficiency.

Increase the modern aesthetic of the factory.

Can check by barcode to increase import and export management efficiency.

Can recognize faces to strictly control import and export goods.

Can connecting other software, other departments can also monitor the inventory management.

The speed of exporting goods is fast, can export 2 trays at the same time.

Check inventory time automatically, avoid the case of expired goods.

Low power consumption helps to save electricity.

1. Receiving goods : The warehouse receives all kinds of materials, semi-finished products or finished products from suppliers or factories for the purpose of manufacturing or processing or assembling.

2. Inventory management: You can check the relevant information of the warehouse at any time, including inventory information, operation information and save the import and export history of goods.

3. Export goods: The warehouse sends goods to the factory for related parts for the purpose of production, processing, assemble,…

| Material | Imported steel |

| Dimensions (Depending on needs, can be up to 100m long, 20m high) | Lenght/height: 100*20m (Max) |

|

The size of the tray has many types: 610x430x100 mm 610x430x150 mm 610x430x190 mm 610x430x310 mm 610x430x390 mm ... |

Depending on needs for customer |

| Tray capacity: Depending on needs | 50 Kg,... depending on needs for customer |

| Number of tray | Maybe hundreds, thousands of trays |

| Power supply | 220V/50Hz |

* According to the needs of customers, we confidently create automatic warehouses with outstanding features, high applicability as well as different structures and operating properties to manage goods most effectively.

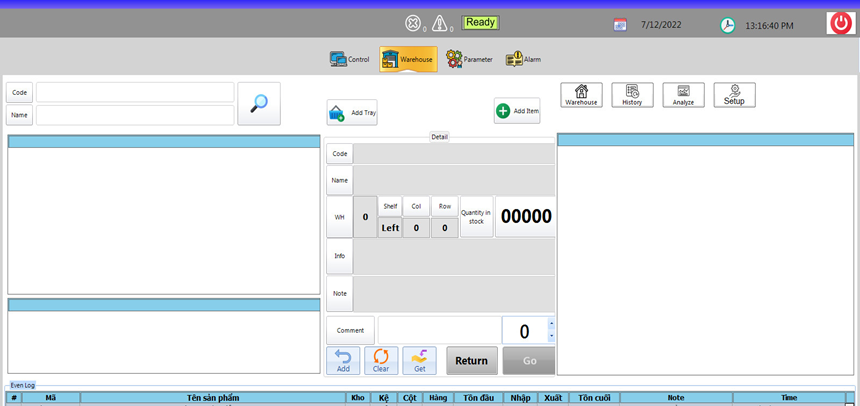

The warehouse system is managed by Vima Warehouse software. The robot is responsible for moving the necessary products to the picking stations, the operator can stay on the spot to pick up the goods.

Vima Warehouse Software

Vima Warehouse Software